Making Sure Durability with Thorough Pipeline Welding Inspection

Making Sure Durability with Thorough Pipeline Welding Inspection

Blog Article

Finest Practices for Pipe Welding Inspection: Methods, Specifications, and Treatments to Achieve Quality Control and Compliance

Effective pipeline welding examination is necessary for ensuring the integrity and safety and security of important infrastructure. By employing a mix of strategies such as visual examination and progressed non-destructive testing techniques, together with adherence to developed industry requirements like those from ASME and AWS, organizations can significantly improve their quality guarantee procedures. However, the execution of these ideal techniques positions numerous difficulties that warrant mindful consideration. Recognizing the intricacies associated with each stage of assessment is crucial to attaining compliance and integrity in pipe systems. What details methods can be employed to browse these challenges effectively?

Importance of Welding Inspection

The honesty of welded joints is paramount in making sure the safety and reliability of pipeline systems. Correct welding strategies and comprehensive inspection procedures are essential to stop failings that can lead to devastating cases, environmental damages, and loss of life. Pipeline Welding Inspection. Welding examination works as a preventive step, determining issues such as cracks, porosity, and incomplete blend prior to they rise right into significant concerns

Furthermore, pipe systems usually operate under high pressure and severe conditions, making the high quality of welds even extra essential. Governing conformity is another significant element, as numerous criteria determine the high quality assurance procedures that should be followed in pipe construction and maintenance. Failure to conform can cause lawful ramifications and financial losses.

The role of welding evaluation expands beyond simple verification of handiwork; it incorporates the guarantee of long-term functional integrity. This involves a systematic technique that includes not just visual evaluations however likewise advanced non-destructive testing techniques. Eventually, effective welding evaluation is a financial investment in the durability and safety and security of pipeline systems, guaranteeing they work as intended while decreasing threats connected with product shortages.

Secret Evaluation Methods

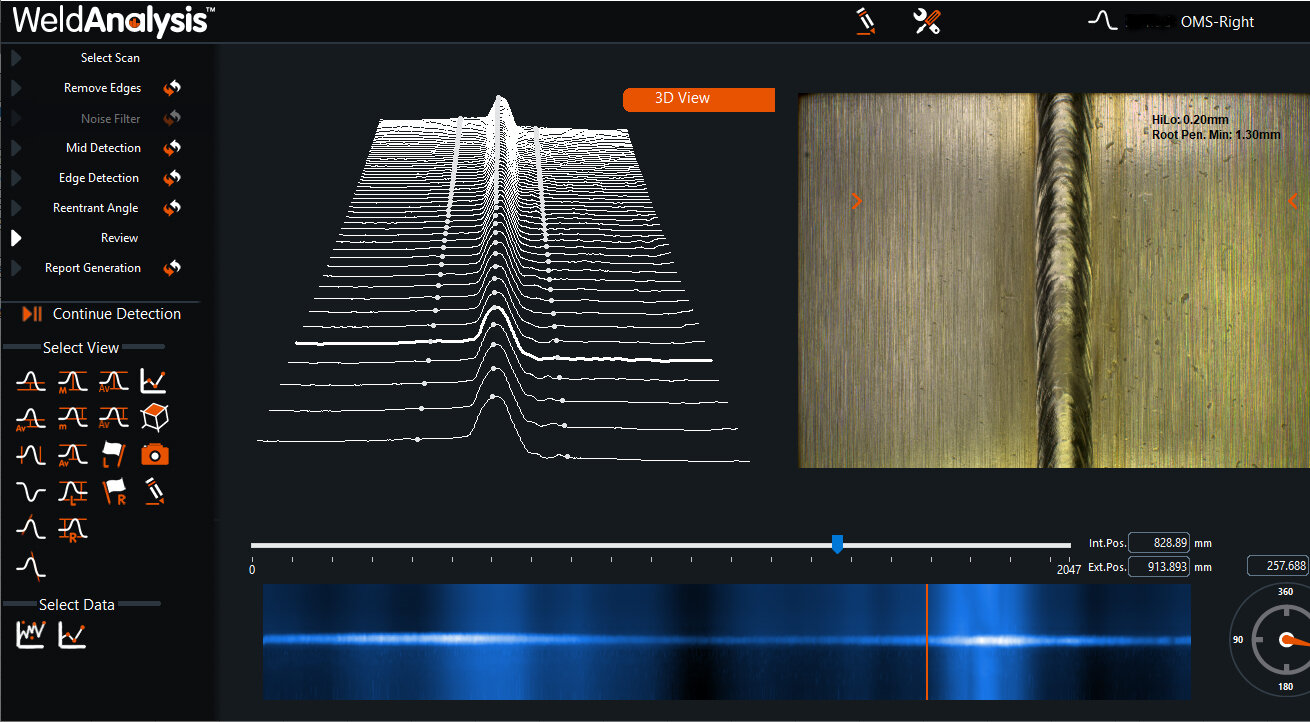

Aesthetic inspection, often the first line of protection, enables the recognition of surface flaws such as splits, undercuts, and porosity. Ultrasonic screening utilizes high-frequency acoustic waves to find internal problems, offering a thorough analysis of weld honesty. This non-destructive method is specifically effective for determining interruptions that may not show up externally.

Radiographic screening includes using X-rays or gamma rays to generate photos of the bonded joint, disclosing inner problems. This method supplies thorough understandings yet may need customized devices and safety and security factors to consider. Lastly, magnetic particle screening works for finding surface area and near-surface suspensions in ferromagnetic products, making use of electromagnetic fields and great iron fragments.

Industry Standards and Laws

Conformity with sector requirements and regulations is important for making certain the high quality and safety of pipeline welding examinations. These requirements offer a framework for best methods in welding procedures, products, and examination strategies, permitting organizations to reduce problems and enhance the honesty of pipe systems. Trick bodies such as the American Society of Mechanical Designers (ASME), the American Welding Culture (AWS), and the International Organization for Standardization (ISO) collection forth guidelines that are extensively recognized and adopted within the industry.

In the United States, laws from the Pipe and Hazardous Products Security Management (PHMSA) govern the safety and security of pipe operations, mandating extensive inspection protocols. These requirements not only serve to safeguard public safety and the setting but additionally ensure conformity with legal and legal responsibilities. Adherence to the relevant codes, such as ASME B31.3 for procedure piping, is necessary for keeping functional effectiveness and regulatory compliance.

In addition, constant updates and modifications to these requirements show technological developments and advancing industry practices, emphasizing the requirement for organizations to remain enlightened and train employees appropriately. Inevitably, durable compliance with recognized standards fosters count on and dependability in pipe facilities, securing both possessions and stakeholders.

Effective Examination Treatments

Effective evaluation procedures are critical for identifying possible issues in pipe welds and making certain the overall integrity of the system. A systematic technique to evaluation incorporates several crucial phases, including pre-weld, in-process, and post-weld examinations. Each stage plays a vital function in maintaining quality control.

Throughout pre-weld examination, it is important to assess the products and joint arrangements, our website guaranteeing compliance with task specifications. In-process evaluations involve monitoring welding strategies and criteria, such as warmth input and you could try this out travel rate, to protect against issues from taking place. This stage permits real-time modifications to welding techniques.

Post-weld examinations consist of non-destructive testing (NDT) techniques like radiography, ultrasonic screening, and magnetic fragment screening. These methods help spot inner and surface area flaws that can endanger the pipeline's functionality. Paperwork of all inspection tasks is paramount, providing a traceable record that supports conformity with sector criteria.

Educating and qualification of evaluation employees additionally improve the performance of these treatments. By sticking to a structured assessment method, organizations can alleviate risks, ensure conformity, and ultimately deliver pipelines that satisfy stringent security and efficiency requirements.

Usual Challenges and Solutions

Pipeline welding inspection offers numerous usual challenges that can influence the quality and safety of the end product. One significant difficulty is the irregularity in welding methods and products, which can bring about irregular weld high quality. To resolve this, it is critical to develop standardized procedures and training for welders, ensuring an uniform technique throughout tasks.

Environmental elements, consisting of temperature and humidity, can additionally impact the welding process, potentially causing splits or incomplete blend. Implementing regulated environments and adhering to pre-weld treatments can mitigate these threats.

Conclusion

In final thought, the execution of best practices for pipe welding examination is essential for ensuring quality control and compliance with market criteria. A detailed method, incorporating different techniques such as visual, ultrasonic, and radiographic screening, facilitates the recognition of issues throughout all stages of the welding procedure. Pipeline Welding Inspection. Adherence to developed policies and effective examination procedures not only boosts the integrity and safety and security i loved this of pipe systems but likewise reduces dangers related to welding flaws, consequently advertising total operational stability

Conformity with sector requirements and regulations is vital for making sure the quality and safety of pipeline welding inspections. These criteria give a framework for best methods in welding processes, products, and assessment methods, permitting organizations to lessen defects and improve the integrity of pipeline systems.In the United States, guidelines from the Pipe and Hazardous Products Security Administration (PHMSA) regulate the safety and security of pipe operations, mandating extensive assessment procedures. An organized method to assessment incorporates numerous essential phases, including pre-weld, in-process, and post-weld inspections.In conclusion, the implementation of ideal practices for pipe welding inspection is necessary for making certain high quality assurance and compliance with sector requirements.

Report this page